What is vitreous enamel?

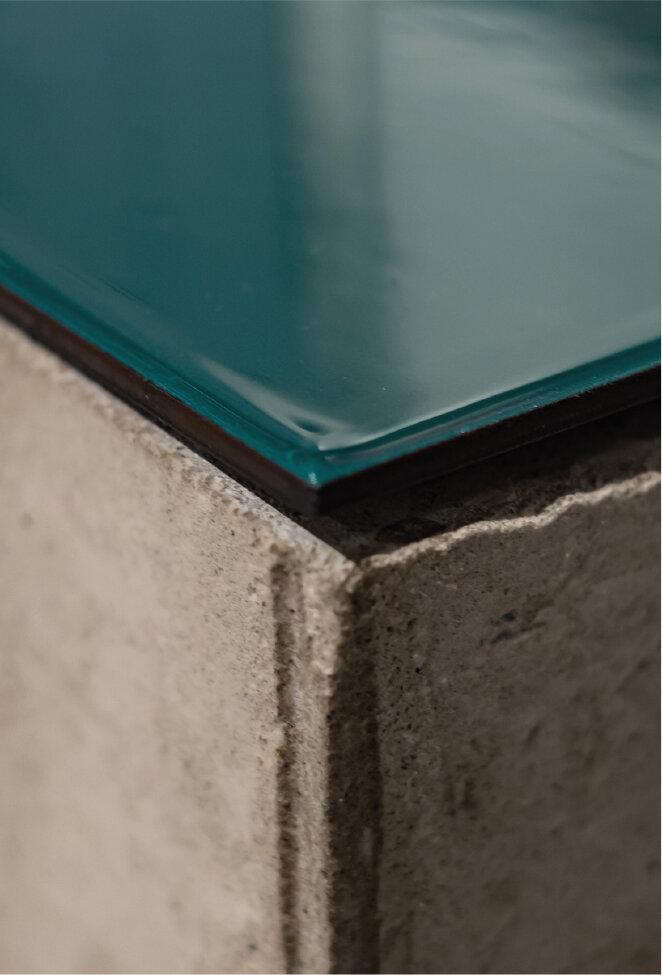

Vitreous enamel is a glassy inorganic coating bonded to metal by fusions at + 800°C.

The coating is created by grinding and mixing enamel frits (glass frits), colour pigments and additifs, which is then applied to the steel surface and fired between 750 and 850 °C. The powder melts, fuses and then hardens to a smooth, durable vitreous coating.

Why choose vitreous enamel?

Water- and corrosion proof

Waterproof and resistant to liquids, with an absorption level of zero.

Resistant to temperature changes

Stays unaffected and distorsion-free from -60 °C up to + 450°C.

Non-Flammable

Does not burn in contact with fire nor does it emit smoke or toxic

substances.

UV and weather resistant

Being 100% UV resistant, its colors remain intact when being exposed to sunlight or other extreme weather conditions.

Chemical and acid resistant

The surface does not get affected by environmental or chemical attacks.

High scratch and shock resistance

Its hard surface gives vitreous enamel a high impact, scratch and

abrasion resistance.

Graffiti Resistant

Graffiti does not hold on a vitreous enamel surface, which makes it easy

to maintain.

Easy to clean

Resistant to any kind of chemical cleaning agent

such as bleach or ammonia (with the exception of descaler).

Ultra-Hygienic

The surface does not give off any harmful substances and is totally suitable for contact with food.

Steel Specifications

Max Steel thickness: 3mm

Max enamelling size: up to 2500 x 1250 mm

(larger sizes are to be discussed)

Colors

Emaillerie Belge has developed over 1800 color possibilities.

Almost all RAL and PANTONE COATED colours are possible, as well as + 800 custom color developments.

Textures & Side Finishes

Emaillerie Belgie offers a wide variety of textures and finishes to suit all kinds of projects. Among them, the following selections are used most frequently:

Textures: Glossy, Matte, Crackled, Gradient, Transparent, HP, Terrazzo

Side finishes: Flat, bevelled, single or fully flanged.